So I have been busy the last few weekends! When I jump into hobbies I jump in full swing, it is a character flaw  ! I have made "sample" bars for myself out of each set to test down the road, and so far I am very glad that I did.

! I have made "sample" bars for myself out of each set to test down the road, and so far I am very glad that I did.

Sorry for the long posts!

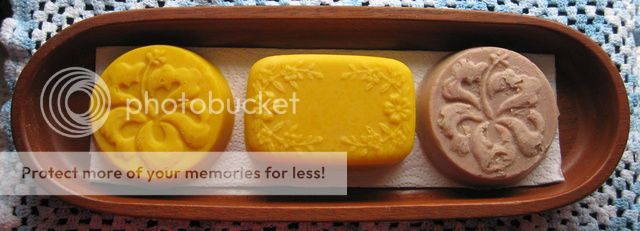

3 weeks ago I did my 1st CP batch. The wife and I love coconut oil so I went with a full 100% CO 20% SF recipe. It traced very fast due to the temps I soaped at. Flowed into the mold great though and firmed up in about 12hrs. The loaf plopped right out of the mold, and cut great after an overnight stint wrapped in a towel. I just used a sample bar last night at the sink and it lathered great. I personally like how it stripped everything off of my hands, but I can see how some consider it drying. No need for lotion for me, the wife may not agree . Currently on week 3 of curing.

. Currently on week 3 of curing.

2nd CP batch was high on CO as well. Over 60% CO and the rest Olive Oil. I added in Tumeric and Pumpkin Pie spice. Any thoughts on where this is going ? It went into the mold at a heavy trace as well but still poured nicely. Again it popped right out of the mold and smelled wonderfully like pumpkin pie. I had my hopes up that it would stick but the CP process is taking another aroma hostage I think. It is still there, but it is very slight. Currently on week 2 of curing.

? It went into the mold at a heavy trace as well but still poured nicely. Again it popped right out of the mold and smelled wonderfully like pumpkin pie. I had my hopes up that it would stick but the CP process is taking another aroma hostage I think. It is still there, but it is very slight. Currently on week 2 of curing.

After cleaning the mold and cutting batch 2 bars I went to CP batch 3. I am a beer geek as well, so I had planned ahead a few days prior and had a flattened Saison in the fridge. I used 100% beer (no H2O.) The lye did act a bit odd. It would settle and I actually had to crush it up a bit in the beer. It would form a hardened disc at the bottom of my cup. It broke up easy but was something I had not encountered before. From my experience using 100% beer accelerated the trace. It was mashed potatoish going into the mold. The top actually hardened quicker than the rest and the cracked. It didn’t volcano, but it did force me to cut off the top layer and mix it back into the still hot middle. The next day the soap came out of the loaf fine but was very soft. 2 weeks later it has definitely hardened some and still smells amazingly like the beer still! Currently on week 2 of curing.

4th CP batch was a week ago. Wife is pregnant and has to limit her coffee intake so I wanted to do a coffee bar for her in the ams. I soaked coffee grounds in sunflower oil 3 days prior. This batch was 16oz CO, 8oz OO, and 6oz SunO (counting the coffee grounds that was soaking as well.) I also put .25oz Vanilla Absolute. If flowed wonderfully into the mold and had setup 12hrs later. It cut into great looking and smelling bars. Coffee has faded definitely but vanilla is still present. The aromas mix well imo! Currently one 1 week of curing.

5th and 6th batches were done Sunday and I went Hot Process… man these were so different. Even after everything I read I was (and still am) not sure if I did everything just right.

For this one I wanted to make something toddler friendly so I searched the web and found a nice castile soap recipe. I went with a 90% Olive Oil and 10% CO recipe. From my books and searching I know true castile is 100% OO but anything above 80% seems to carry the castile label. With my crockpot that I purchased for this there is a lot of surface area being cooked at once so I expected my batch to neutralize in around an hour and a half. It was actually neutral and vasoline like in a little over an hour. I had bought dinosaur silicone mold along with a few animal and small bar silicone molds. Mistake #1 was not trying to get the soap into the mold quicker. I slathered some into a dino mold and by the time I got my next spatula full of soap over it had already decided to harden up on. It didn’t fully harden but it was now pulling away from the mold every pass of the spatula. After about 30 mins of fussing, saying words I usually only use when working on cars, and fighting I had all the molds filled. I finally just said to heck with it and slathered a lot of soap into the mold filling it up to the edges of the silicone. My game plan was to simply cut them out into the shapes with an exacto knife after they came out of the mold. They were solid enough to pop out today with minimal hassle. I just am not “impressed” with the visual appearance of these. The molds were great I just find it hard to see how I can get the detail these molds present to appear in HP soap. Any tips on this (aside from banging it on the table it is silicone after all?.?.) I have a feeling this recipe would be ideal in a loaf setting. I think this type of soap might have issues taking to a detailed mold very well. Possibly might try this CP to have a more "pourable" mixture.

Last batch was another beer soap using an NC native Amber Ale. Same ratios used as the Saison beer soap. Again it sat 3 days to go flat and I encountered the same issues with the lye clumping and solidifying as I did previously. Again crushing it up worked fine. This thing separated in the crockpot in about 15 mins, came back together and was thick mashed potato in about 30 mins. It was vasoline stage in another 10 mins or so but was not neutral. This was my issue I believe. It took another 30 in the vasoline stage to go neutral. Even with the top on, it was drying out and I had a clumpy mess on my hands going into my 2lb silicone loaf mold. I struggled for about 20 mins trying to form this into a load but I could still see some pockets through the mold. I covered it to try and apply some pressure overnight to get rid of as much air as I could. This am it fell right out of the mold. The top and bottom were fairly crumbly. I said what the heck and started cutting. Crumbling stopped and I have some fairly decent bars. Still a few misshapen bottoms due to air pockets but nothing I cant trim if it bothered me that bad. I took a sample bar and used it this am. Smells very similar to the Saison bars but I added some paprika to try and redden it up to minimal avail. I think it was just to clumpy to disperse evenly.

I am pondering rebatching this to try and get a smoother loaf out of it. I ended up with over a solo cup of crumbles just from the beer soap bar this am.

I am definitely enjoying the thought process through all of this. I love the science in this sort of thing which is why I am into brewing beer too! I am hoping to get some pics up soon for these as well! Thanks for listening to all of this for those that made it this far!!!

Sorry for the long posts!

3 weeks ago I did my 1st CP batch. The wife and I love coconut oil so I went with a full 100% CO 20% SF recipe. It traced very fast due to the temps I soaped at. Flowed into the mold great though and firmed up in about 12hrs. The loaf plopped right out of the mold, and cut great after an overnight stint wrapped in a towel. I just used a sample bar last night at the sink and it lathered great. I personally like how it stripped everything off of my hands, but I can see how some consider it drying. No need for lotion for me, the wife may not agree

2nd CP batch was high on CO as well. Over 60% CO and the rest Olive Oil. I added in Tumeric and Pumpkin Pie spice. Any thoughts on where this is going

After cleaning the mold and cutting batch 2 bars I went to CP batch 3. I am a beer geek as well, so I had planned ahead a few days prior and had a flattened Saison in the fridge. I used 100% beer (no H2O.) The lye did act a bit odd. It would settle and I actually had to crush it up a bit in the beer. It would form a hardened disc at the bottom of my cup. It broke up easy but was something I had not encountered before. From my experience using 100% beer accelerated the trace. It was mashed potatoish going into the mold. The top actually hardened quicker than the rest and the cracked. It didn’t volcano, but it did force me to cut off the top layer and mix it back into the still hot middle. The next day the soap came out of the loaf fine but was very soft. 2 weeks later it has definitely hardened some and still smells amazingly like the beer still! Currently on week 2 of curing.

4th CP batch was a week ago. Wife is pregnant and has to limit her coffee intake so I wanted to do a coffee bar for her in the ams. I soaked coffee grounds in sunflower oil 3 days prior. This batch was 16oz CO, 8oz OO, and 6oz SunO (counting the coffee grounds that was soaking as well.) I also put .25oz Vanilla Absolute. If flowed wonderfully into the mold and had setup 12hrs later. It cut into great looking and smelling bars. Coffee has faded definitely but vanilla is still present. The aromas mix well imo! Currently one 1 week of curing.

5th and 6th batches were done Sunday and I went Hot Process… man these were so different. Even after everything I read I was (and still am) not sure if I did everything just right.

For this one I wanted to make something toddler friendly so I searched the web and found a nice castile soap recipe. I went with a 90% Olive Oil and 10% CO recipe. From my books and searching I know true castile is 100% OO but anything above 80% seems to carry the castile label. With my crockpot that I purchased for this there is a lot of surface area being cooked at once so I expected my batch to neutralize in around an hour and a half. It was actually neutral and vasoline like in a little over an hour. I had bought dinosaur silicone mold along with a few animal and small bar silicone molds. Mistake #1 was not trying to get the soap into the mold quicker. I slathered some into a dino mold and by the time I got my next spatula full of soap over it had already decided to harden up on. It didn’t fully harden but it was now pulling away from the mold every pass of the spatula. After about 30 mins of fussing, saying words I usually only use when working on cars, and fighting I had all the molds filled. I finally just said to heck with it and slathered a lot of soap into the mold filling it up to the edges of the silicone. My game plan was to simply cut them out into the shapes with an exacto knife after they came out of the mold. They were solid enough to pop out today with minimal hassle. I just am not “impressed” with the visual appearance of these. The molds were great I just find it hard to see how I can get the detail these molds present to appear in HP soap. Any tips on this (aside from banging it on the table it is silicone after all?.?.) I have a feeling this recipe would be ideal in a loaf setting. I think this type of soap might have issues taking to a detailed mold very well. Possibly might try this CP to have a more "pourable" mixture.

Last batch was another beer soap using an NC native Amber Ale. Same ratios used as the Saison beer soap. Again it sat 3 days to go flat and I encountered the same issues with the lye clumping and solidifying as I did previously. Again crushing it up worked fine. This thing separated in the crockpot in about 15 mins, came back together and was thick mashed potato in about 30 mins. It was vasoline stage in another 10 mins or so but was not neutral. This was my issue I believe. It took another 30 in the vasoline stage to go neutral. Even with the top on, it was drying out and I had a clumpy mess on my hands going into my 2lb silicone loaf mold. I struggled for about 20 mins trying to form this into a load but I could still see some pockets through the mold. I covered it to try and apply some pressure overnight to get rid of as much air as I could. This am it fell right out of the mold. The top and bottom were fairly crumbly. I said what the heck and started cutting. Crumbling stopped and I have some fairly decent bars. Still a few misshapen bottoms due to air pockets but nothing I cant trim if it bothered me that bad. I took a sample bar and used it this am. Smells very similar to the Saison bars but I added some paprika to try and redden it up to minimal avail. I think it was just to clumpy to disperse evenly.

I am pondering rebatching this to try and get a smoother loaf out of it. I ended up with over a solo cup of crumbles just from the beer soap bar this am.

I am definitely enjoying the thought process through all of this. I love the science in this sort of thing which is why I am into brewing beer too! I am hoping to get some pics up soon for these as well! Thanks for listening to all of this for those that made it this far!!!