Draugr Rekkr

Active Member

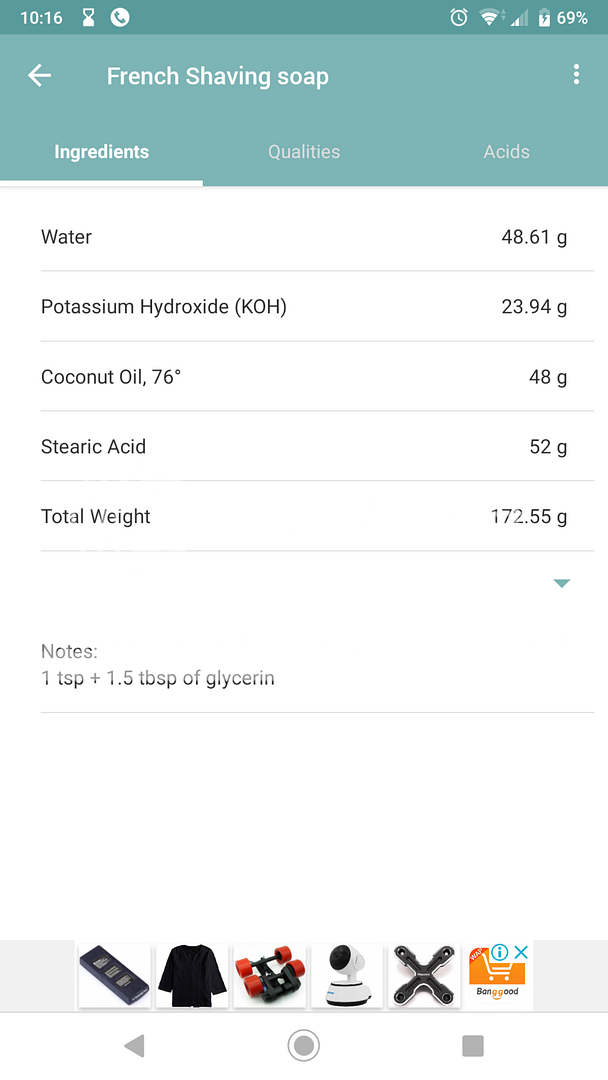

Okay so the recipe is super simple. This will be a small batch of about 100g of oil.

I don't have a crock pot or a double boiler so I improvised. I cranked up the heat and way I go.

It worked! Did I mention I've never done a HP soap.

Added the KOH and that happened fast.. I was going to use auto mixer but I didn't really have enough in there to do it properly so I went and hand whisked it. Came together really fast.!

I don't know why but it started to crumble..

The double boiler didn't work for this case so I through it straight in the pot (possible mistake?).

Heat goes back up and I'm keeping an eye on it for anything unusual (not that I would know what that would be so I'm just trying to make sure it doesn't burn). Can soap burn?

Repoured and looks a little better this time.

Few hours later and it works! Not as much slip as I expected but I just added a little bentonite clay since I use throw away blades for my straight razor.

One to two hours after whiping it up with a fake bristle brush. 12 hours and a shower later. Still good.

Conclusion:

There's some bubbles in the bars of soap now that it's set up but I don't really know if that's normal or how to remove them. Either way I think it was a success and I'm happy with how it turned out. I look forward to making it a bit better or at lest find a way to get the soap to come out less like cooked rice first time.

Special thanks goes to @IrishLass for linking the thread to me.

Thank you too @songwind for starting the thread as well as @DeeAnna for the inspiration for the double boiler.

References:

https://www.soapmakingforum.com/threads/my-first-shaving-soap-is-a-success.34264/

P.s. If anyone has any ideas on what I did wrong and how I can fix it then please let me know.

Attachments

Last edited: