MullersLaneFarm

Well-Known Member

I haven't been this excited about making soap in well over a decade!

I've been reading posts here and on the FB group CPLS, pouring over files, recipes and watching videos for 3 weeks.

I'm not one to just grab someone else's recipe and go with it (what fun is there in that?)

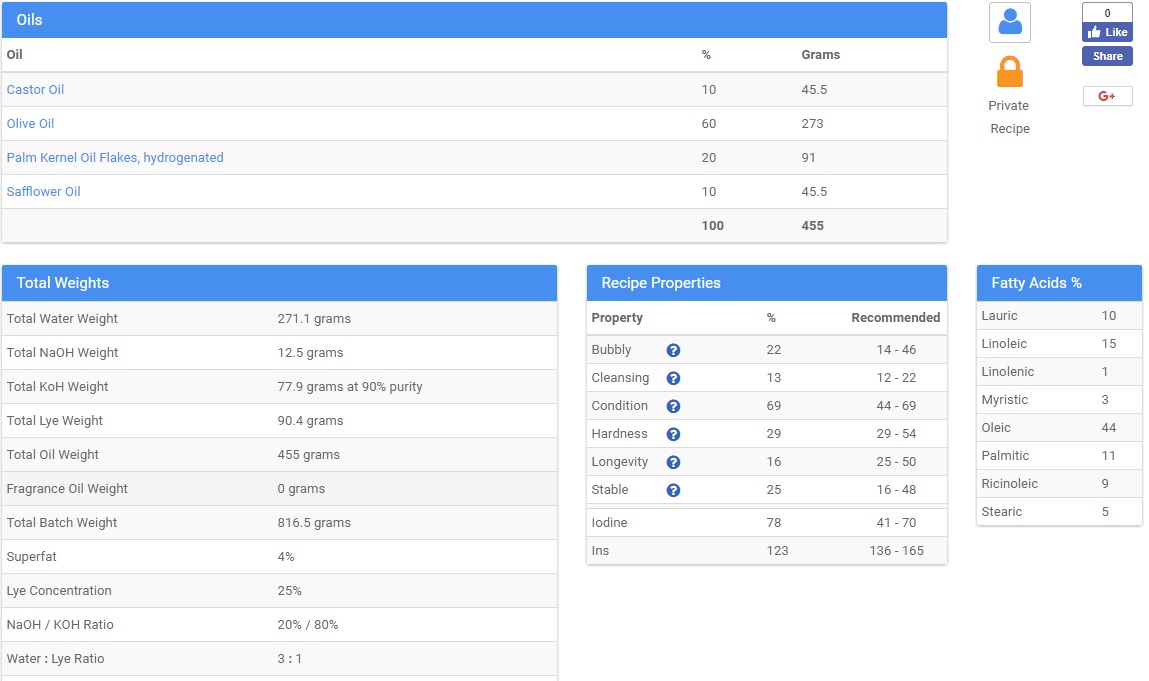

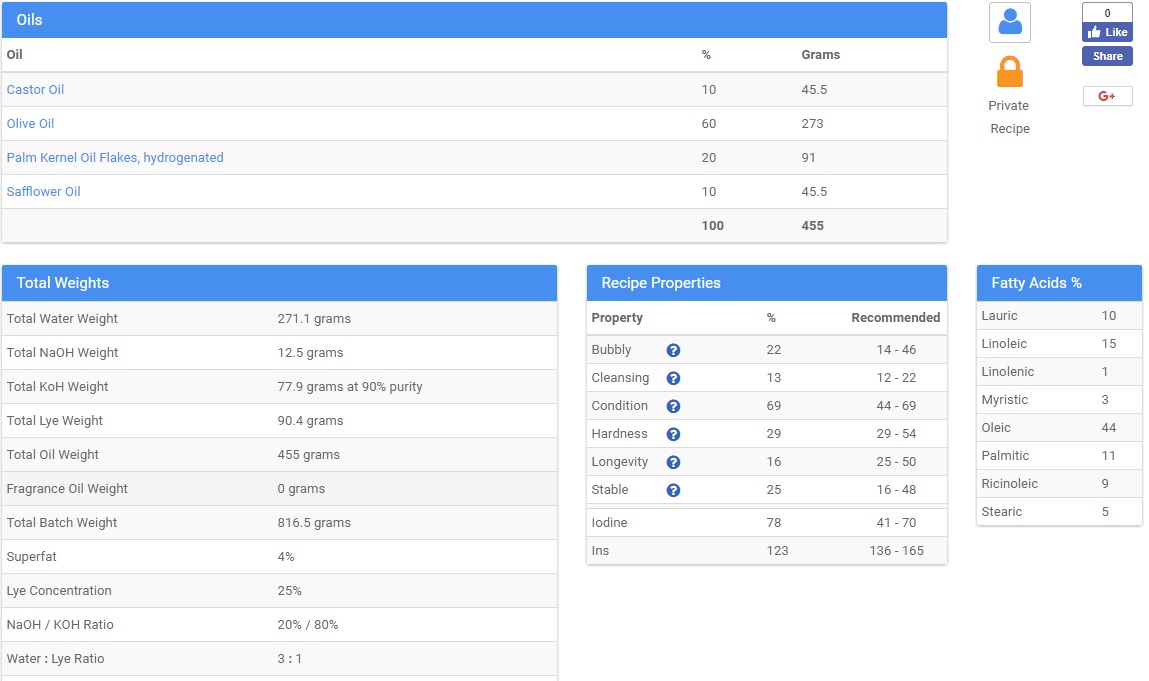

My recipe:

I used 1:2:1 water:glycerin:total lye for my lye solution

Of course I couldn't stick with just that ... not with a little jar of honey sitting within finger's reach. While I was stick blending the to emulsify, I added a little less than a teaspoon of honey because ... well, I'm a beekeeper and everything is better with honey!

Of course, that made the beautiful amber color turn a dark brown. I'm okay with that because I plan on putting the LS into ceramic pump bottles.

I stick blended about 10 minutes, covered with plastic wrap and left it alone for 20 minutes and decided to take a look ....

Pulled my little spatula around ...

A couple stirs ...

So ..... is it looking okay??

I'd like to hear opinions (good & bad) about the recipe.

During dilution, I plan on adding 3% sodium lactate, 1.96% EDTA & .15% polysorbate 80

ETA: Holy crow!! I just checked it ... just a little over an hour after I poured the lye into the oils and it has No Zap! How can this be?? (and my hands feel great!)

I've been reading posts here and on the FB group CPLS, pouring over files, recipes and watching videos for 3 weeks.

I'm not one to just grab someone else's recipe and go with it (what fun is there in that?)

My recipe:

I used 1:2:1 water:glycerin:total lye for my lye solution

Of course I couldn't stick with just that ... not with a little jar of honey sitting within finger's reach. While I was stick blending the to emulsify, I added a little less than a teaspoon of honey because ... well, I'm a beekeeper and everything is better with honey!

Of course, that made the beautiful amber color turn a dark brown. I'm okay with that because I plan on putting the LS into ceramic pump bottles.

I stick blended about 10 minutes, covered with plastic wrap and left it alone for 20 minutes and decided to take a look ....

Pulled my little spatula around ...

A couple stirs ...

So ..... is it looking okay??

I'd like to hear opinions (good & bad) about the recipe.

During dilution, I plan on adding 3% sodium lactate, 1.96% EDTA & .15% polysorbate 80

ETA: Holy crow!! I just checked it ... just a little over an hour after I poured the lye into the oils and it has No Zap! How can this be?? (and my hands feel great!)

Last edited: